Our Products for Industrial Markets

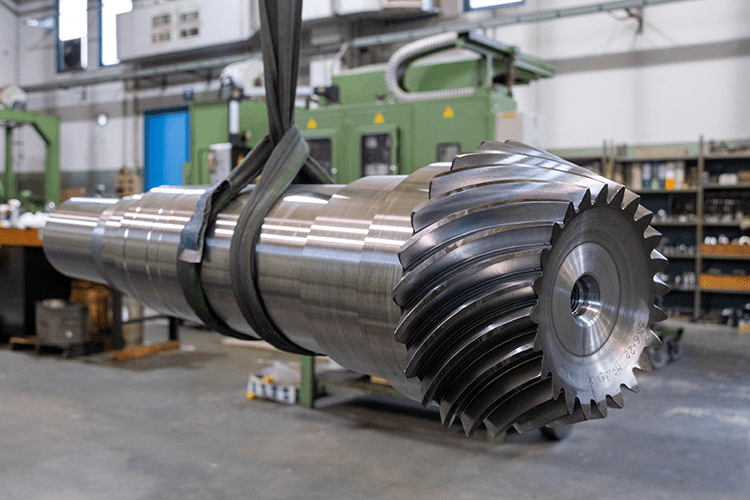

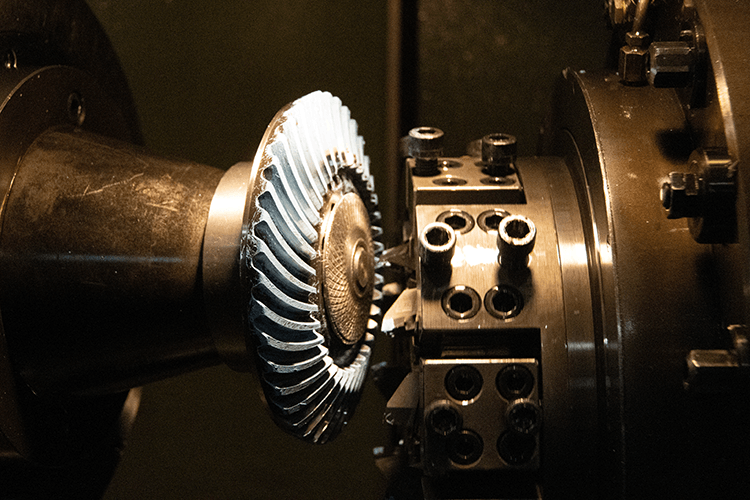

The manufacture of these spiral bevel gear pairs is carried out on very powerful cutting machines, which cut the teeth in continuous motion and generate them by envelope through the cyclopalloid system.

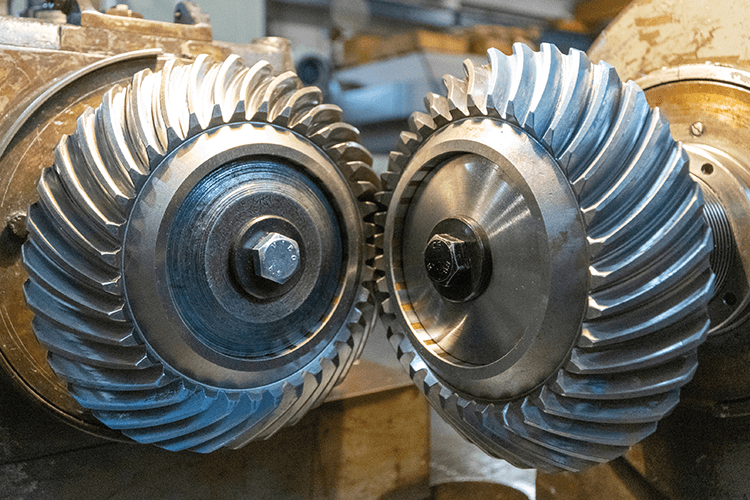

The Klingelnberg bevel gears offer the opportunity - with the same dimensions - to have 30-40% higher transmission power compared to Gleason bevel gears.

The Klingelnberg bevel gears allow wide advantages both for assembly and for deformations under load without any substantial change in the point of contact and the contact itself.

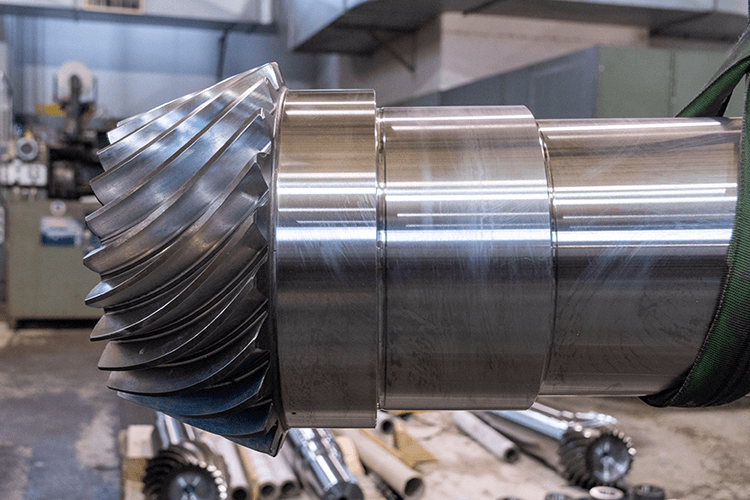

In addition, we use the HPG-S rectification system.

The rectification of the teeth is carried out with tungsten carbide and borazon blades, materials supplied exclusively by General Electric.

This processing method involves the centesimal removal of chips with the final effect of the complete absence of micro-cracks and burns on the surface of the teeth, ensuring extremely silent operation.

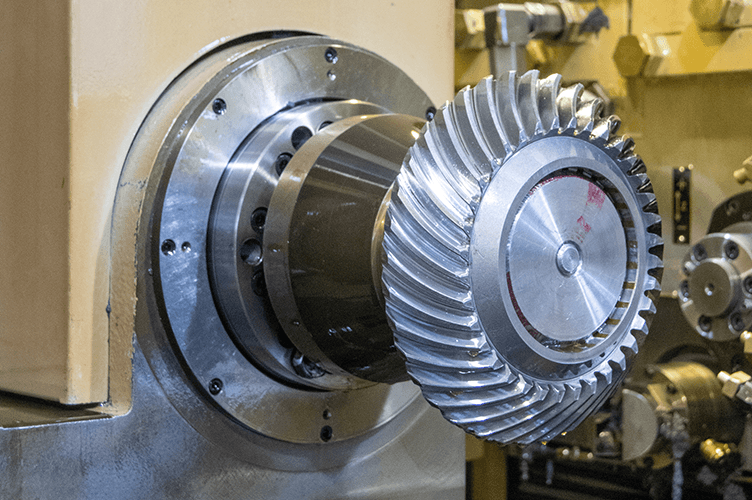

The Klingelnberg bevel gears offer the opportunity - with the same dimensions - to have 30-40% higher transmission power compared to Gleason bevel gears.

The Klingelnberg bevel gears allow wide advantages both for assembly and for deformations under load without any substantial change in the point of contact and the contact itself.

In addition, we use the HPG-S rectification system.

The rectification of the teeth is carried out with tungsten carbide and borazon blades, materials supplied exclusively by General Electric.

This processing method involves the centesimal removal of chips with the final effect of the complete absence of micro-cracks and burns on the surface of the teeth, ensuring extremely silent operation.